Hand tools

- NEW! Stainless Sleeve Hand Swager

- NEW!

Stainless Sleeve - Hand Swager (for aluminum sleeve)

- Oval Sleeve (aluminum)

- NEW!

Bolt Cutters - NEW!

Rebar Cutters - NEW! Stainless Sleeve Swagers (cordless,electric)

- NEW!

Cordless, Electric,Hydraulic Swagers (for aluminum sleeve) - NEW!

Wire Rope Cutters

ARM

ARM

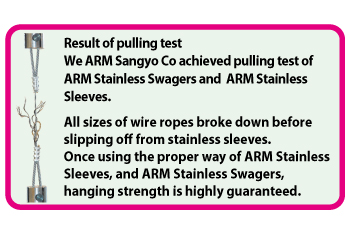

Stainless Sleeve Hand Swagers

Stainless Sleeve Hand Swagers Cordless,Electric

Cordless,Electric Hand Swagers

Hand Swagers ARM Oval Sleeves

ARM Oval Sleeves